Open the shell of the hard disk, we can clearly see the internal structure of the hard disk. After observing and understanding, the hard disk can be divided into a magnetic head assembly, a magnetic head drive assembly, a disk, a spindle assembly, a front control circuit and the like.

Head assembly

The head assembly mainly consists of three parts: the read/write head, the transmission arm and the drive shaft. The most important part of the head assembly is the head. The other part is the auxiliary mechanism of the head. The drive shaft drives the transmission arm to bring the head to the specified position.

The magnetic head is a tool for reading and writing in the hard disk. It can be said that it is one of the most precise components in the hard disk. The magnetic head is made by winding the hard disk coil around the magnetic core. The principle is that the resistance value of the special material will change according to the magnetic field. Change, that is, what we call susceptor. When the hard disk is working, the head reads the data by reading the magnetic field change on the hard disk. Instead, you can write data by changing the magnetic field on your hard disk. In order to prolong the service life of the hard disk and avoid the wear of the disk and the magnetic head, the magnetic head is not in contact with the disk, but in order to ensure the accuracy of reading and writing, the distance between the magnetic head and the disk is only 0.1-0.3 um, and after the power is turned off, the magnetic head will Automatically reverts to the landing zone, at which point the disc no longer reads data. Therefore, the accuracy of the drive is very high.

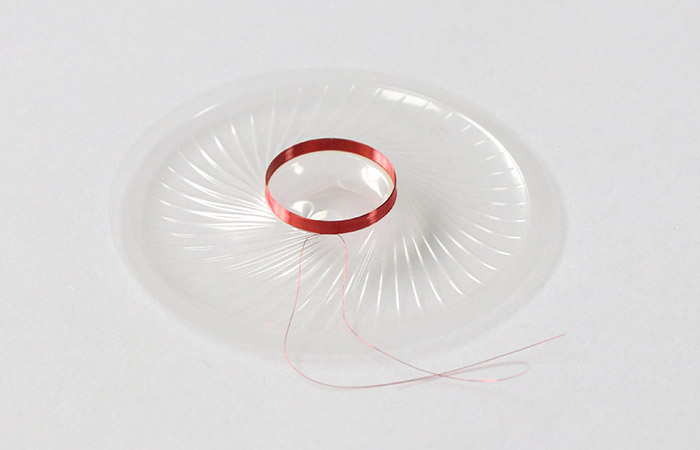

In addition, the length of the hard disk seek time is also very close to the head drive assembly. The driving mechanism of the magnetic head is composed of an electromagnetic coil motor, a magnetic head driving trolley, and an anti-vibration mechanism. Only the high-precision magnetic head driving can correctly drive and position the magnetic head, and can find the system-specified magnetic track in the shortest time to ensure the hard disk energy. Perform reliable reading and writing. Electromagnetic coils are critical in electromagnetic drive assemblies. The diameter of the electromagnetic coil, the density between the wires, the material of the coil, and the shape of the coil all have strict requirements and must conform to the overall design of the hard disk. Therefore, in the production of hard disk coils, the production requirements of the hard disk coil must be met, and a change in parameters may affect the read and write capabilities of the entire hard disk.

The hard disk coil is a special-shaped coil. It is different from the circular coil and square coil that we usually touch. It is usually wound on a profiled wire mold or pulled by a circular coil. The direct winding on the mold requires attention to the magnitude of the tension and Winding speed and other factors; and the hard disk coil obtained by pulling up must also strictly control the size of the pulling force to avoid damage to the entire coil caused by damage to the surface insulating paint.

Inquiry

Inquiry