Headphone speakers are everywhere in our daily lives. Many people have more than one earphone. As an important output device, headphones play an indispensable role in our lives. In subways, buses, plazas, parks and other places, people can use headphones to listen to music and make phone calls. The main advantage is that you can immerse yourself in the world without affecting the people around you.

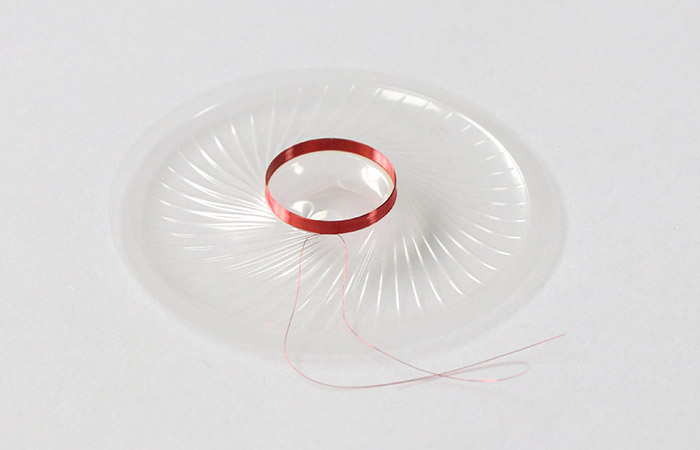

The diaphragm of the earphone is the sounding component of the earphone, which determines the sound quality of the earphone to some extent. There are many materials for the diaphragm, such as PET/PEN/PEI/PI/LCP/PEEK/PC/PPS/PAR, etc. To sum up, today we mainly discuss the influence of the structure of the diaphragm on the sound quality. If you know the internal structure of the headphone speaker, you can know that the diaphragm structure can be divided into two types, one with a copper ring on the edge and the other without a copper ring (we become a common horn diaphragm). The stability of the film during vibration to avoid distortion of the sound after prolonged use. The high-end earphone speakers on the market basically use copper ring diaphragms, such as Apple headphones, Huawei headphones and so on.

Correspondingly, the manufacturing process of the copper ring earphone is higher. During the process of the voice coil winding and the film bonding, the copper ring of the diaphragm is relatively rigid and is not easily deformed, and the automatic winding device is used to make the mold. After that, the diaphragm with the copper ring is placed therein, and after the coil is wound, the film is sequentially bonded to the film, and the film is taken out from the mold by the robot to be placed in the groove of the turntable, first glued, and adhered to the voice coil. Hehe. In this process, the error of the diaphragm copper ring is required to be in a very small range, otherwise the diaphragm may be placed in the groove and cannot be removed or damaged, which may damage the diaphragm and increase the defect rate.

Due to the small space of the earphones, the diaphragm for drinking is also very small, and the effect of a small error sound quality is very large. In the process of glue and bonding, the concentricity of the voice coil (the center of the diaphragm coincides with the center of the voice coil) is very high. After the voice coil diaphragm is bonded, the shape of the glue should be consistent, and the error is controlled at 20 Within the wire.

In addition, there are many kinds of patterns on the surface of the diaphragm, such as round lines, sun patterns, water ripples, and the like. The various patterns mainly increase the role of the reinforcing ribs, increase the rigidity of the vibration of the diaphragm and increase the effective radiation area of ??the diaphragm, and also have a certain effect of improving the damping. The deeper the grain, the greater the medium frequency density and the clearer the intermediate frequency.

With the improvement of living standards, the requirements of various accessories in the headset market are gradually increasing. This is the embodiment of consumption upgrade, and low-end products will gradually be eliminated by the market. Core Yun Technology specializes in providing high-end voice coils and speaker-related accessories.

Inquiry

Inquiry