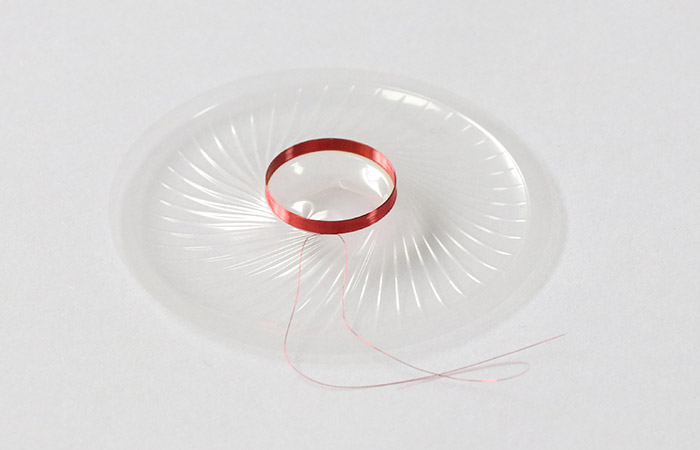

In the production process of micro-speakers, there is an important process, that is, the voice coil diaphragm is bonded. Voice coil patch bonding is an important factor affecting speaker quality. Voice coil diaphragm bonding generally uses UV glue, and currently manufacturers in the domestic market use solvent glue. The advantage of solvent glue is that the price is low, but it also has the following shortcomings:

1. Solvent glue will cause pollution to the environment.

2. Long-term use can cause harm to the human body. Since the principle of the bonding of the solvent glue is to cause the adhesion of the surface of the adherend by the volatilization of the solvent. Therefore, the solvent glue has a volatile property, and the volatile component is generally toxic. The use of solvent glue can cause environmental and human contamination.

3, solvent glue is a flammable, explosive dangerous goods, the safety hazard in the production, packaging, storage, transportation process is greater than the UV glue.

4. The utilization rate of solvent glue is not high, generally it is about 30%. Waste glue will cause waste, and the disposal of waste will also increase the cost.

All these drawbacks lead to the limitations of the future development of solvent glue, and gradually replaced with new glue, most of the speaker headset customers have been replaced by UV glue for bonding. UV glue, also known as photosensitive glue, UV curing glue, can be used as a bonding agent, or as a rubber compound for paints, coatings, inks, etc.

Then the bonding effect of UV glue is affected by those factors.

Roughness

The surface roughness of the material to be bonded will affect the bonding effect, and the surface has a certain roughness to improve the bonding strength of the UV glue. However, the surface which is too rough cannot infiltrate the UV adhesive well, and the residual air at the beginning of the concave will affect the bonding effect.

2. Cleanliness

The diaphragm label will easily absorb dust and other foreign matter, which will also reduce the contact strength of the UV glue.

3. Surface structure

The composition and structure of the diaphragm have an important influence on the UV bonding performance, durability, heat aging performance, etc., and the influence of the surface structure on the adhesion of the UV adhesive is determined by the shape, thickness and surface material of the diaphragm.

Inquiry

Inquiry