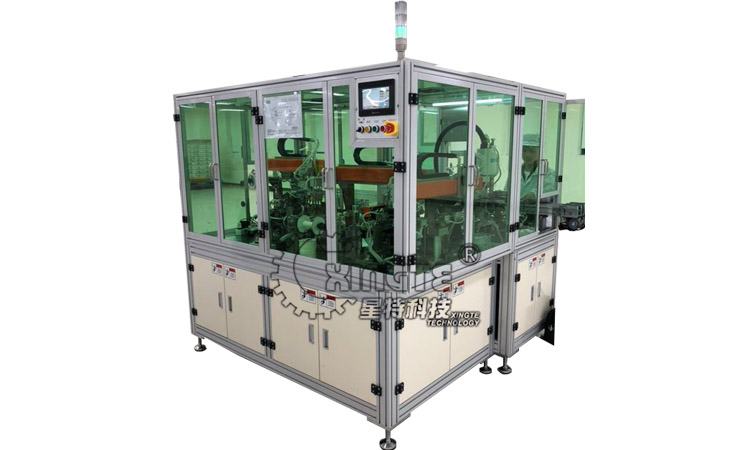

Equipment Overview:

This equipment is a new type of automatic equipment specially developed for welding of heating core of electronic cigarette and winding process of cotton thread.The equipment is customized and developed according to the customer's requirements. The touch welding line system has high precision and stable welding effect. It can directly connect with the cotton wire winding process of the electronic cigarette heating core. The process connection is smooth, which can greatly improve the work efficiency and reduce the manual work.

Equipment features:

The equipment adopts advanced servo control system, which can automatically adjust the relevant actions according to the parameter command input by the operator to meet the requirements of welding and winding; the main parts are imported servo motor, hollow platform, linear guide rail, screw rod, etc., with high transmission precision, stable operation and long service life.

The equipment can be connected to the automatic production line of heating core cotton wire winding of electronic cigarette, which does not need manual operation in the whole process. It has high degree of automation, stable operation of the equipment, small occupation space and high yield rate of finished products. It can not only save labor costs, but also produce products with higher requirements.

Field of application:

Electronic cigarette production

Equipment parameters:

|

name |

parameter

|

name |

parameter |

|

model |

XT-PHJ |

Number of axes |

16axis |

|

Dimensions |

2600(L)×1800(W)×1900(H)mm

|

Spindle speed |

≤3000rpm

|

|

Machine weight |

About 1.2t

|

Power consumption |

About 3.5kw/h |

|

Power Supply |

AC220 V ± 10% single phase50/60Hz |

control mode |

touch screen |

|

Air source |

0.4Mpa~0.7Mpa

|

Tension device |

damper |

|

capacity |

900-1200pcs per hour |

||

Equipment appearance:

Inquiry

Inquiry