Equipment Overview:

This equipment is a new machine specially designed for producing VCM frame coil.The existing xt-666s (wheelbase 36mm), high precision winding machine, products can achieve mirror effect, widely used in computers, webcams, scanners

Equipment features:

The winding machine adopts advanced CNC motion controller,The display screen is programmed by itself, which is easy to operate. The motion controller can perform high-precision linear positioning, arc interpolation, spiral wrapping and other actions. The transmission part adopts Yaskawa servo motor and THK high-precision grinding screw rod, which has the characteristics of high rotation speed, accurate positioning and long service life, and has made safety structure design, which is more secure. It has self-provided air heating device, and each main unit has its own air heating deviceThe shaft has independent air outlet, which makes the winding product more stable

Special coils can be designed according to customer requirements.

Field of application:

Mobile phone VCM motor coil, camera motor coil

Equipment parameters:

|

name |

parameter

|

name |

parameter |

|

model |

XT-666 |

Number of winding spindles |

6axis |

|

Dimensions |

710(W)×1400(L)×1820(H)mm

|

Spindle speed |

≤4000rpm

|

|

Machine weight |

About 320kg |

Applicable wire diameter |

0.02-0.15(mm) |

|

Power Supply |

AC220 V ± 10% single phase 50 / 60Hz |

Coil height |

≤20mm |

|

Power consumption |

About 4kw / h |

Coil outer diameter |

≤ φ 20mm (special customizable)

|

|

Air source |

0.4Mpa~0.7Mpa

|

Lead wire position |

The angle can be set arbitrarily

|

|

Spindle direction |

Clockwise / counterclockwise

|

Length of outgoing line |

1-50mM (special customizable) |

|

Step memory capacity |

99999 |

Thread cutting mode |

Custom blade cutting |

|

Control mode |

touch screen

|

Tension device |

Servo tension device |

|

Number of control axes |

4Axis servo |

Coil curing mode |

Curing by heating |

|

capacity |

600-800 pcs per hour (take 70 cycles per layer and 4 layers of circular skeleton as an example) |

||

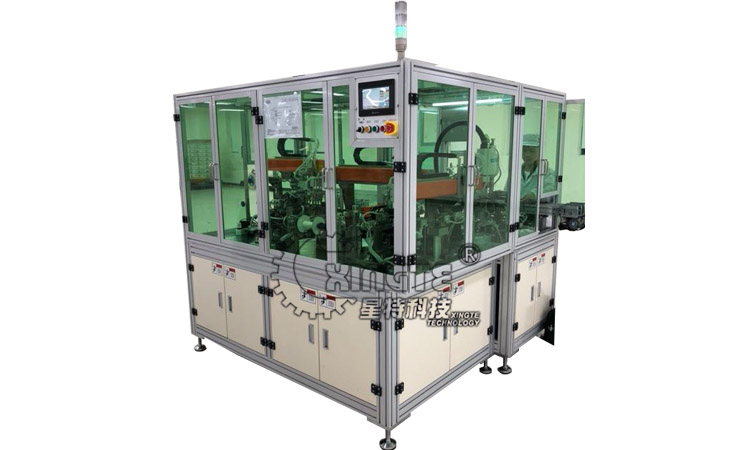

Equipment appearance:

#FormatImgID_0#

Inquiry

Inquiry