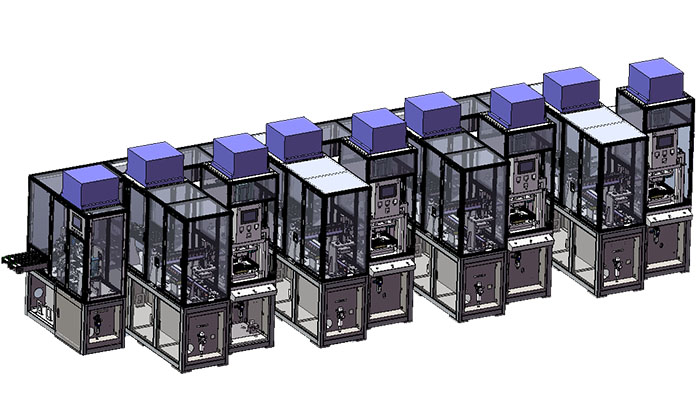

At present, there are many types of non-standard equipment. Although they are non-standard, they must follow certain principles, including force structure, load-bearing range, protective measures, etc. When it comes to a personalized society, the original national and industry standards obviously cannot meet consumption Needs of users, so non-standard customized equipment may become the blue ocean of the industry.

What is non-standard

Non-standard customized equipment does not produce substandard products, but surpasses the existing national standards and industry standards to form a new standard. Since the relevant regulations have not kept up, the industry threshold is relatively high. On the one hand, it must meet the requirements of service providers. Requirements, on the other hand, it must also meet the relevant laws and regulations and technical standards of various regions.

Where is the brilliance of non-standard

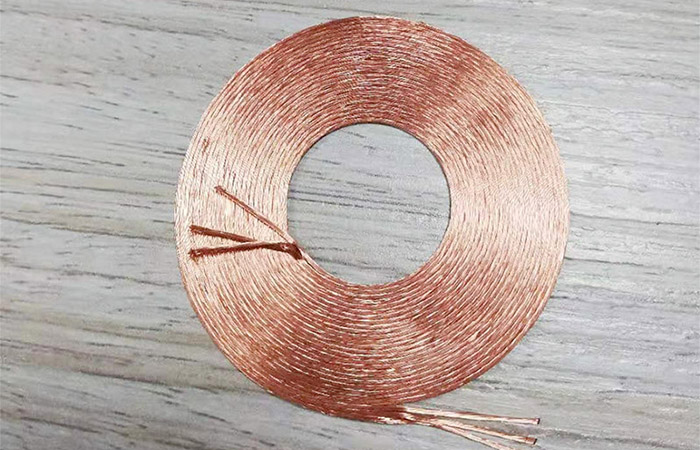

In order to provide a better customer experience, some non-standard equipment service providers often need to amplify some of the functions of the equipment or add other functions to a device to meet the needs of some customers. Compared with various standard equipment , Non-standard equipment has to invest a lot of manpower and material resources in R&D, design or production and debugging.

Charges

Due to the different customization requirements of customers, it is difficult to organize production. Sometimes a set of design plans need to be modified repeatedly, and the mold and production process must be re-formulated. Compared with standardized equipment, the later charge may be more than 4 times higher. Units should understand and be fully prepared. At the same time, the budget should be larger to be able to meet the requirements of equipment manufacturers at any time. The production of non-standard equipment often takes longer and requires patience.

The threshold of the non-standard customized equipment industry is relatively high, but it represents a future in this field. At present, especially in the electronic product industry, product updates are fast. If the previous standard equipment is still used for production, it is obviously unable to meet the requirements. Non-standard customization of production equipment is needed. At present, non-standard facilities only account for 6.5% of all orders in the industry, but the new demand each year will increase on the basis of the previous year. Manufacturers must be ready to welcome the era of personalization at any time. And has sufficient production capacity. In addition, if the order volume of non-standard equipment is larger, the R&D cost spread to each machine is lower, so manufacturers can also make reasonable considerations based on their own demand.

Inquiry

Inquiry